Why Did We Need an Industrial Sewing Machine?

We’d been getting by with our Janome HDs. They sew through 8 layers of denim without even breaking a sweat. They are strong and trouble free. They’ve been with us for so long and they’re wonderful for sewing draperies and most upholstery. But some recent projects (topstitching vinyl for restaurant bar stools and table toppers), as well as some leather projects on the horizon, had us searching for an industrial sewing machine.

We needed to be able to topstitch easily, through many layers, with consistent stitch lengths. We needed to sew leather. We needed to be able to hem the sticky vinyl that just didn’t want to slide easily through our old machines. We needed a compound feed walking foot industrial sewing machine.

Compound Feed Walking Foot Sewing Machine

A compound feed walking foot sewing machine is a beast. It not only pulls the fabric from the bottom with the feed dogs, but it pulls with a walking motion of the inner presser foot and by a needle that lifts up and forward with every stroke. Using this mechanism, the compound feed walking foot sewing machine can sew through many layers without letting them slip or get out of alignment. The walking foot also can go up and over uneven seams without changing the stitch length as our Janome would do. The Janome would do several short stitches as it climbed up and over thick seams. The walking foot just goes right over without a problem, with strong even stitches.

But where do we start our search? Where do we buy an industrial machine? We can find them on Amazon. We can see them in Youtube videos and read about them in our favorite upholstery books (check out Spruce: A Step-by-Step Guide to Upholstery and Design). But how do we choose and where can we see one in person?

Our search started in our hometown of Springfield, Missouri. We visited our local sewing machine shops and were told that residential sewing machines and industrial sewing machines are completely different. They told us that they might sell Pfaff household machines, but they don’t even have an account for Pfaff industrial machines. One helpful sales lady suggested that we go visit Springfield Leather Company.

First Try: The Cobra Class 20 at Springfield Leather

Springfield Leather Company has a great selection of machines that are set up for, you guessed it, sewing leather. We tried out the Cobra Class 20 there. It was a great machine. It had a couple of features that we ended up requesting in our final machine: a servo motor and a speed reducer.

Industrial sewing machines come with a choice of either a servo motor or a clutch motor. There are a couple of big differences. First, the servo motor is nearly silent, while the clutch motor hums constantly anytime the machine is turned on. Second, the servo motor has adjustable speed and is easier to start slowly while the clutch motor starts off at a high speed (this is great for production facilities that just need to sew long distances, quickly). So for an industrial machine beginner, the servo motor is much easier to use and leads to fewer mistakes.

A speed reducer is a feature common on sewing machines set up specifically for sewing leather. The speed reducer allows you to sew slowly and carefully when doing detailed work. The speed reducer also maintains the power of the machine so that the needle doesn’t get stuck in the leather when going slowly. We really liked this feature on the Cobra and it was noticeably missing on one of the other machines that we tried later.

After sewing leather with the Cobra Class 20, we were pretty convinced that it was the machine for us. We decided to sleep on it and bring back some upholstery material to try out the next day. The Cobra sewed leather very well, however it did not do well on our upholstery fabric. One reason is that the feed dogs on the Cobra Class 20 are smoothed out so that they don’t puncture or damage leather. These smooth feed dogs didn’t get a good grip on our fabric. Another reason is that the machine was outfitted with a very narrow set of presser feet for sewing detailed leather work. So, the finished seam on our upholstery fabric had a very gathered and uneven look. We decided to continue searching for our perfect machine.

Second Try: A Trip to St. Louis

We did some online research and reading and decided that we really wanted to see a Consew 206RB-5. It is the favorite of many upholsterers and is considered to be one of the best. We decided that we’d drive to St. Louis to see one in person, or so we thought.

I made the call the day before to a store in St. Louis that advertised the Consew 206RB-5. I asked if they had them in stock – he replied that he’d rather sell me a Tacsew something something something. I said I might be able to be persuaded, but I wanted to see them in person – did he have them on the floor? Could I try them out? He answered yes to all my questions, but little did I know that he was merely telling me that he had a couple of Tacsews on his sales room floor and yes, he’d be able to sell me one of those tomorrow.

So we excitedly drove to St. Louis. We just knew that we’d be driving home with a new sewing machine in the back of our SUV. We were so excited to go to a place that had all the sewing machines that we had read about. We’d be able to compare them side by side!

We arrived at the store and walked in to find many household sewing machines and vacuum cleaners. We searched and finally found two, yes TWO, Tacsew sewing machines. That’s it! That’s all! No Consew machine to try. In fact, they hadn’t sold a Consew out of the store for 10 years!

Well, Robbyn is not easily deterred. While I endured the Tacsew salesman (read below under “Stitched Seam Comparisons” for details about sewing with the Tacsew), she googled and found another sewing machine store in nearby St. Charles, Nick-O Sewing Machine.

Third Time’s a Charm: Nick-O Sewing Machine

Robbyn got Nick, from Nick-O Sewing Machine, on the phone and he agreed to stay open late to wait for us to get to his store. When we arrived at the Nick-O Sewing Machine store in St. Charles, we got to see the rows of industrial machines that we’d been expecting all along. Nick showed us a Highlead, a Juki and a Seiko sewing machine.

We sewed a lot on the Highlead, but we were never fully convinced that it was the machine for us. Read below in “Stitched Seam Comparisons” for a detailed description of sewing with the Highlead.

We liked the Juki, but it was quite a bit more expensive than the Highlead and Seiko and Nick didn’t think the price difference was justified for our needs.

The Seiko was not assembled. It was just sitting on the table, but after much discussion, Nick persuaded us that the Seiko would be the perfect machine for us. He suggested a servo motor and added a leather package which included the speed reducer and an edge guide, but NOT the troublesome smooth feed dogs and narrow presser feet. He also added single and double welt feet and zipper feet.

We asked how we’d ever be able to assemble this machine in Springfield. Nick replied that they would deliver it assembled at the beginning of the next week. He also assured us that if we didn’t like the Seiko (since we hadn’t been able to try it out) that he’d exchange it for a different machine if necessary.

We left the shop and immediately began googling Seiko sewing machines. We couldn’t believe we’d just bought this sewing machine without ever trying it and without doing any research about it! But we were quickly reassured when we learned that Seiko is the manufacturer of many sewing machine brands. In fact, Seiko had made the Consew 206RB when the Consew was made in Japan. Wow! What relief! This may in fact be the machine for us!

Delivery of the Seiko STH-8BLD-3

So, Nick arrived with our assembled Seiko sewing machine. He removed the plastic wrap, carried it into our shop and showed us how to thread it. Robbyn and I both sewed on the Seiko before he left and were super happy with how easy it was to use.

The Seiko STH-8BLD-3 started off smoothly and quietly and didn’t have any of the extreme tension of the other machines that we had tried. The thread easily pulled out through the machine so sewn pieces could be removed. Other machines had so much tension that it felt like a tug of war to get our fabric out of the machine. Yes, I know that the tension can be adjusted, but there’s a smoothness to the Seiko that the other machines lacked.

Stitched Seam Comparisons

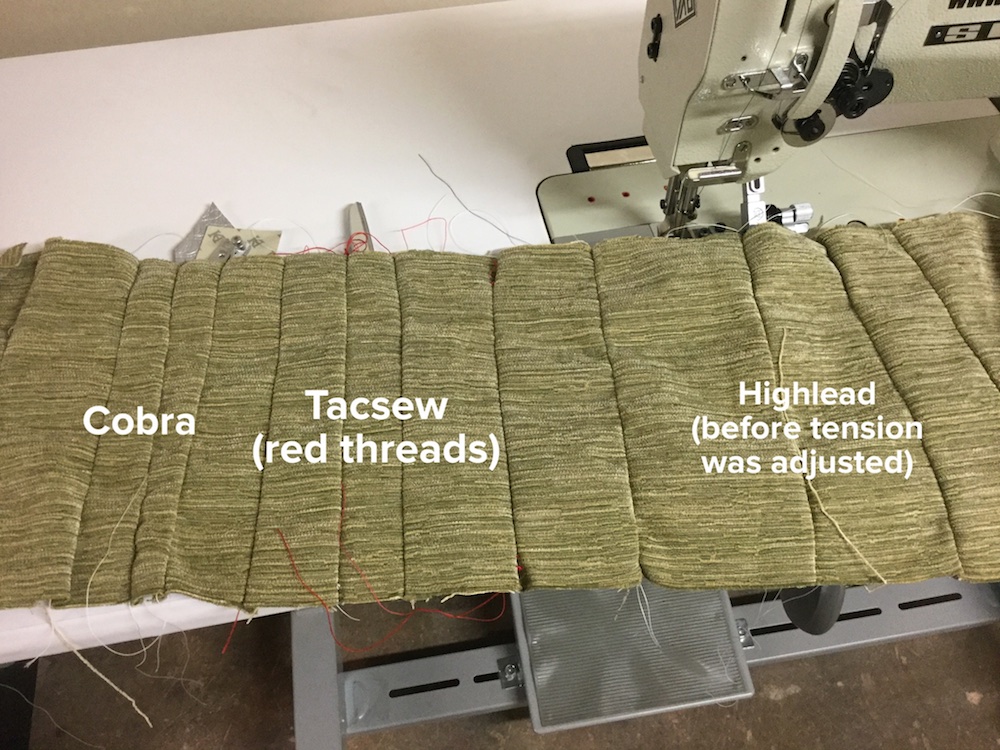

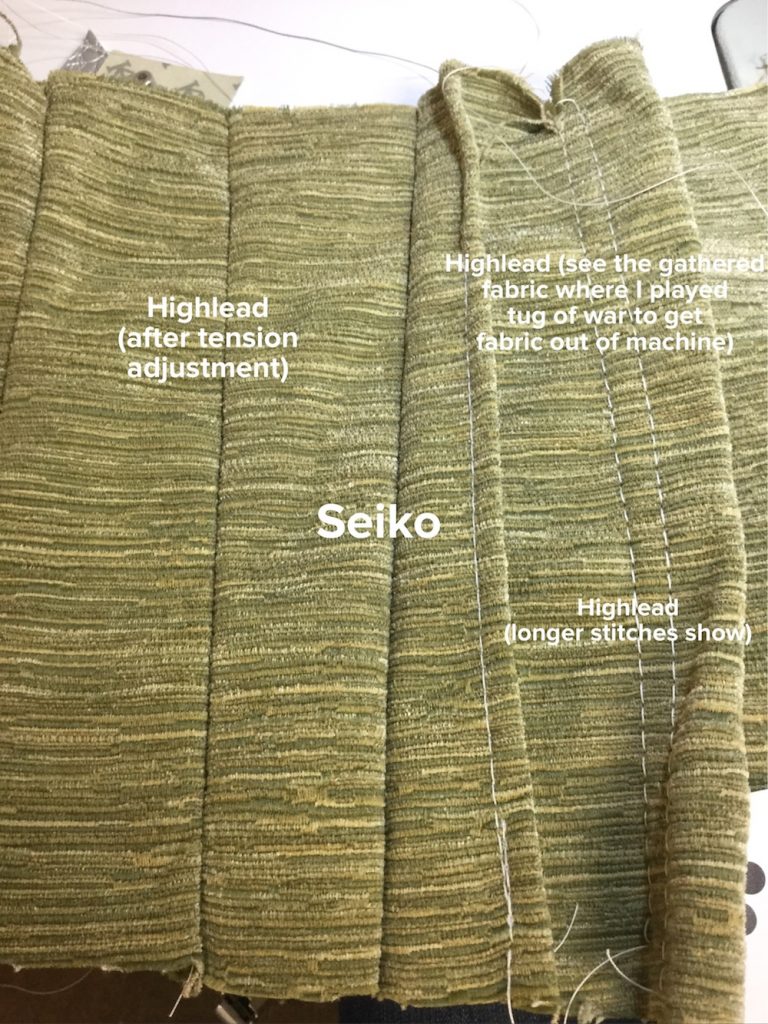

We had a long strip of upholstery fabric that we used to compare the machines. As you can see in the photo below, the Cobra’s smooth feed dogs didn’t grip the upholstery fabric well and resulted in an inconsistent seam. The Tacsew produced a reasonable seam, but stalled out at slow speeds and had to be pushed along by pulling on the hand wheel (that’s when we saw the need for a speed reducer). The Highlead was originally set up for leather and after tension adjustment, was able to produce a fairly smooth seam. But it was still difficult to remove the fabric from the machine. Even with lifting the presser foot high with the knee lift and raising the thread take up lever to the upmost position by turning the hand wheel, the Highlead and Tacsew both made fabric removal difficult. You can see the gathered seam in the top of the second photo where the thread gathered the seam as I pulled to remove the fabric.

The Seiko produced smooth even stitches and smooth flat seams. Sewing on the Seiko was very comfortable. I’m struggling to think of a word to describe the feel of this machine that is more descriptive than smooth. I could use fluid, effortless, gentle, uniform…can you tell I opened a Thesaurus? Sewing with the Seiko just feels right. It’s NOT more expensive than the other machines. It’s right in the middle of the price spread. But it feels luxurious. I guess you’ll have to take my word on that or try one yourself. I really don’t think you’ll be disappointed.

As you read the descriptions of the machines, you might question why we didn’t pick the Highlead. After the tension adjustments, it did sew well. We considered the Highlead as our second choice and Nick offered to bring them both to the shop and let us try them out side by side. But ultimately, it came down to the tight, high tension feel of the Highlead vs. the smooth sewing ease of the Seiko.

Highlights of the Seiko STH-8BLD-3

All of the technical details are available in the Seiko STH-8BLD-3 Brochure, on the Seiko website.

There are many features on the Seiko, or any industrial machine, that you don’t normally see on home sewing machines.

First, the knee lift – you can see it in the picture below. You press the knee lift to the right with your right knee and the presser foot lifts (33/64″ or 13mm) so that you can use both hands to hold your fabric and place it in the machine.

Second, as you can see below, there’s an edge guide that Nick-O-Sew installed as part of their leather package. The edge guide lifts up and out of the way when you’re not using it, but easily is set down to help you sew a consistent seam allowance from the cut edge of your fabric.

Third, there is a bobbin winder on the right side of the machine. That bobbin is there winding all the time as you sew. It stops winding automatically when it is full. Look back at the first picture under “Delivery of Seiko…” and you’ll see the tan thread on the thread holder. That thread on the right is there just to fill bobbins. In that picture, the gray thread is going through the needle for sewing. So you’ll always want to order two spools of a thread color to use in an industrial machine.

Fourth, is the separate sewing machine head and motor. In the photo below, you can see the servo motor with the adjustment knob on the front. Here, it is set to SLOW for beginners. The large pulley you see to the right of the servo motor is the speed reducer. The speed reducer helps you to sew slowly but also maintains torque at low speeds.

The fifth and HUGE difference from a home sewing machine is the compound feed walking foot. In the photo below, you can see the presser foot. It is made of two parts. The outside foot presses down on the fabric, while the inner foot lifts up and “walks” onto your fabric – (this makes it a walking foot machine). The needle also lifts up and forward with every stitch. When the needle moves up and forward (needle feed) on a walking foot machine, this makes the machine a compound feed walking foot machine. If the needle doesn’t move forward, it’s just a walking foot machine. There are also machines out there that only have needle feed with a standard presser foot. They’re called needle feed machines. Other designations for the compound feed walking foot machine are triple feed, unison feed or compound walking foot (meaning the needle, feed dogs and feet all work together to move your fabric through the machine and keep it aligned).

We hope you’ve enjoyed reading the story of our search for an industrial sewing machine. We fully realize that we are new to this industrial sewing machine scene and only hope that this info will help you if you’re also considering moving from a domestic machine to an industrial one. We’ll keep you updated as we gain knowledge and experience with our new Seiko!

Watch the video below to see the compound feed walking foot machine in action!

Seiko Update

So we’ve used our Seiko on several upholstery projects and I have to say we are just as happy, or maybe happier, than the day it was delivered. The Seiko continues to sew strong even stitches through every fabric we choose. It is also wonderful for making welting. The single welt cord foot keeps everything together as we stitch the yards and yards of welt cord required for each project.

We had a learning curve for inserting the bobbin, but one call to Nick-O sewing machine solved our problems. Their mechanic, Reabon, patiently talked us through the problem we were having and now we’re replacing bobbins easily. This confirms the wise words we found on the internet about buying an industrial machine – “Buy from a reputable sewing machine company so that you’ll have someone to help you and to service the machine if necessary.” We have appreciated the expertise of Nick-O-Sewing Machine so much and are thankful for their amazing customer service. We are so glad that we have them to call when we need help.

We hope that you’ll consider a Seiko if you’re in the market for an industrial machine. It really has been better than we could have hoped. Our only problem now is deciding who gets to sew on the Seiko. In fact, we’ll be adding another one to the shop in the near future.

417-429-1243

417-429-1243 hello@BridgeWorkroom.com

hello@BridgeWorkroom.com